February 9, 2021

Since the spring of 2017 when Stone Bank Farm and Market first opened up to the public, a lot has changed. On the market side: Goods and services have been added and a fully-staffed kitchen offers grab & go, farm-to-table soups, apps and entrees, as well as regular public cafes and dinners —- with much more to come! The farm hasn’t stood still either, as increasing demand has warranted the addition of a pack shed and 4,000 square feet of greenhouse space that allows us to now operate year-round.

Given our growth, the farm staff has been on a mission this winter to implement ways that we can work more efficiently —- the end goal being to minimize waste in time, energy and product, while maximizing on the quality and quantity of what we can offer our customers in the space that we have.

Many of our ideas for farming efficiently have come from farmers around the country via their books, podcasts, YouTube videos or on social media, while other ideas have come from thinking creatively about how we can work smarter, not harder. Below are just some of the “efficiencies” that we’ve been able to implement this winter so that we can hit the ground running come spring:

Greens Bubbler

We could not be more excited about our new DIY greens bubbler (a.k.a. Spinach Spa) which Farmer Kim’s handy husband, Matt, built from PVC and a couple of air pumps. As a result of a system that agitates the greens for us, we’ve minimized the need for human-powered greens cleaning (which, in the past, meant submerging our hands and arms into icy cold water for minutes at a time). Another plus: We can now actually walk away for a bit to complete other tasks in the pack shed while the greens are being cleaned!

Do-It-Yourself Germination Chamber

This past fall, when we moved the grow room out of the market basement and into a re-purposed walk-in cooler in the pack shed (because we needed more space), we left behind a germination chamber that was built into one of the basement closets. A germination chamber is a must-have since it decreases the amount of time it takes for the seeds to germinate (sprout) and improves germination rates. So —- Kim had an old non-working refrigerator brought into the packshed, and with the addition of a constantly-running, water-filled crockpot that sits on the floor of the fridge, our greens and micros get the heat and humidity that they need for a successful start.

Grab & Go Tools

With so much to do on the farm each day, time is precious. The last thing we want to be doing is searching for tools! We’re an organized and tidy bunch by nature, but this winter we decided to go a step further by keeping the tools that we use frequently in one easy-to-access area that is close to the gardens and greenhouses. Tool-rule #1: Any tool that isn’t in use somewhere on the farm must be returned to this space.

Over the years SBF has developed an efficient system for storing produce at various stages of production. Different-colored tubs are used for different stages in the process (black for just-harvested, clear for just-washed and brown for market-ready). Different colored tubs even have their designated spaces in the walk-in cooler, and all tubs, when filled with veggies, are labeled and dated. After tubs have been in use, they are washed, dried and returned to their proper place.

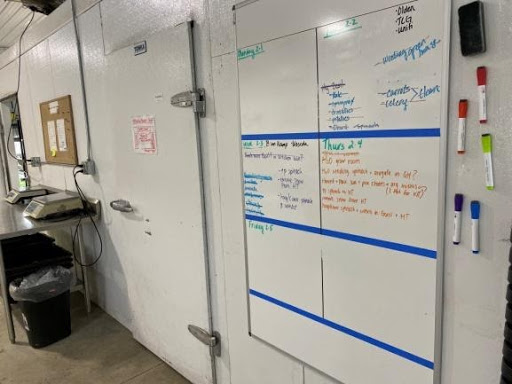

The Mother Board and To-Do Board

Photo on left: We’ve always had a white board for our daily “to-do’s” on the farm, but this winter, we’ve installed a much larger board that allows us to see the week at a glance. Most mornings, we briefly meet in front of the board so that the staff is clear on what needs to be done that day. We can also see who is assigned to which tasks.

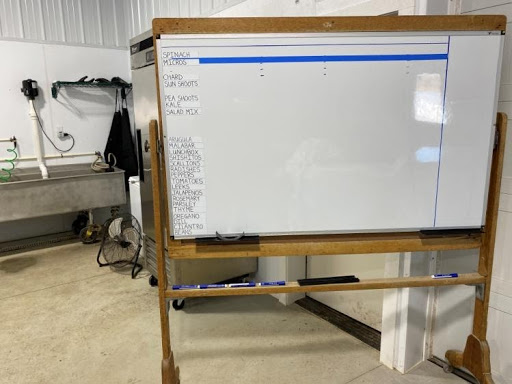

Photo on right: Still a work in progress, a repurposed antique chalkboard which we’ve named, The Mother Board, will allow us to view, at a glance, what’s been harvested, washed, and packaged for that week (and what still needs to be done), and also see the type and quantity of produce needed for the kitchen and market. When peak growing season hits, and farm staff are spread out in all directions, this Grand Central Station of white boards will provide easy-to-access info for staff and volunteers.

In the Hopper

With more ideas in the hopper for improving our farm’s efficiency, we hope that our efforts trickle down to our customers in terms of the quality of our product. Not to mention — doing things more efficiently certainly makes our work a heck-of-a lot easier!

The SBF Farm Crew from l to r: Danika, Kim, Maggie & Jen